Product Description

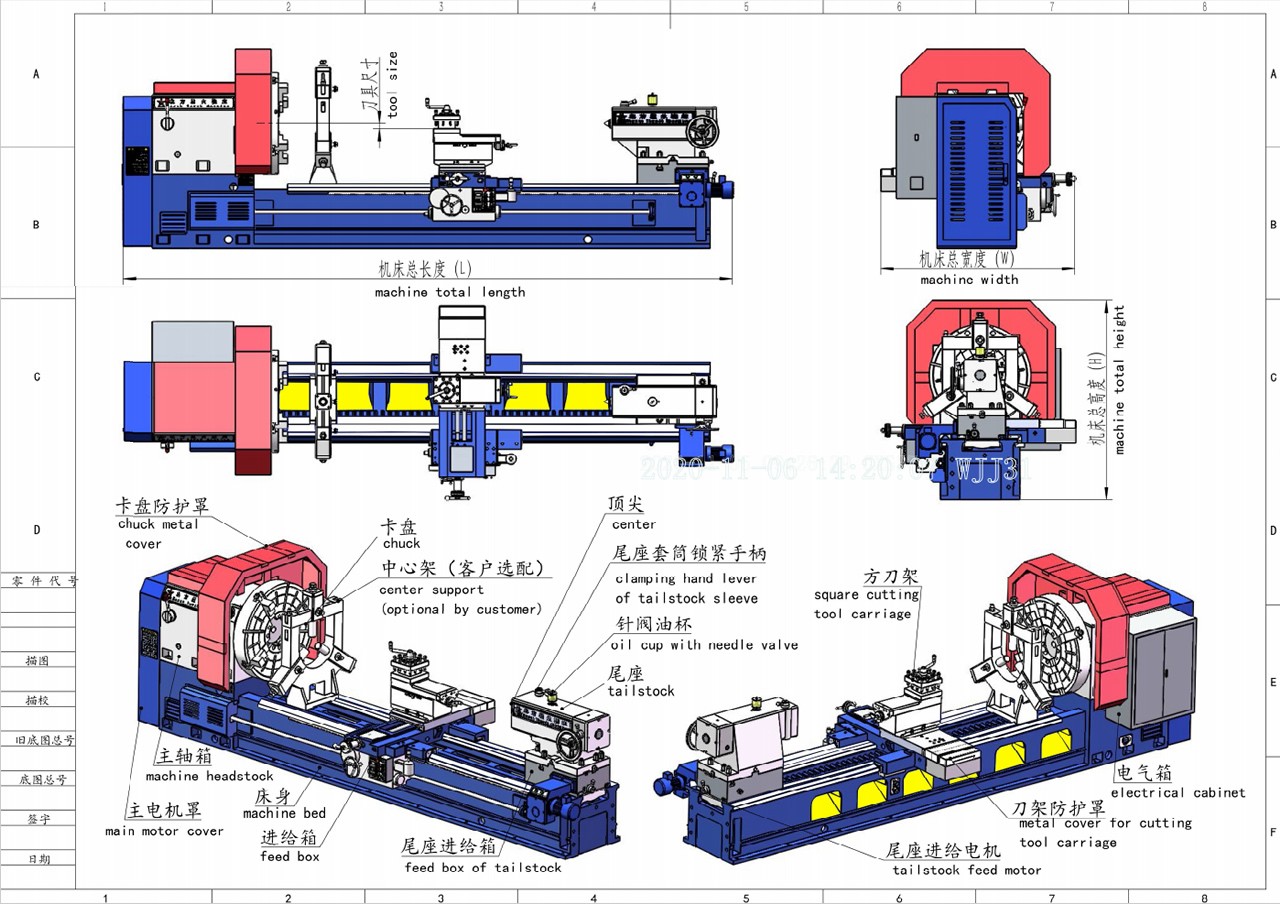

CG series heavy duty horizontal lathe is an electromechanical machine tool integrating electrical control, hydraulic control, modern machinery design and other disciplines, Our heavy duty horizontal lathe executes national lastest accuracy standard, which is designed and manufactured according to the international advanced technology and our many years experience. This kind of horizonta lathe has a perfect structure performance with high rigidity, longer service life, higher efficiency, safe and stable function with easy operation.

1.CG series Heavy duty horizontal Lathe Series are widely used for turning not only the non-ferrous metals like various structure steels, casting steels and irons, but also the external/internal cylindrical / conical/ spherical surfaces, thread of non-metal materials and all kinds of the surface of curve rotary body.

2.Main transmission and feed transmission of CG series heavy duty horizontal lathe adopts separate structures.

3.The machine bed of CG series heavy duty horizontal lathe adopts 3 guide rails, which adopts grinding process or inlaid steel structure of low friction & sliding flat guide rail.

4.The main transmission of CG series heavy duty horizontal lathe is driven by the AC motor directly. It realizes different spindle speeds by 3 different mechanical gear shifts.

5.The main shaft of headstock is a cross-axle structure, which adopts double-row short cylindrical roller bearing with high precision and adjustable radial clearance. and adopts a larger spindle diameter and the best supporting span through optimization design, which improves the rotary accuracy and dynamic and static stiffness of the spindle.The center on the spindle adopts the flange type short taper shank structure, which improves the connection rigidity between the center and the spindle.

6.The horizontal direction of cutting tool carriage uses trapezoidal screw or ball screw, and the longitudinal direction adopts high precision gear and double-teeth rod gap clearance structure. Which improves the transmission accuracy of cutting tool carriage.

7.The tailstock is a kind of intergal box structure, the inner shaft adopts double-row short cylindrical roller bearing with high precision and adjustable radial clearance, and the center is a kind of flange type short taper shank, so that the tailstock has high rigidity. The sleeve and tailstock are both automatic and driven by the motor and equipped with hydraulic force measuring device.

8.This kind of heavy duty horizontal lathe can be also installed double cutting tool carriages, milling & boring device, and cooling device.

Datas

| X61 Heavy Duty Horizontal Lathe |

| Model | Unit | CX61160 | CX61200 | CX61250 | CX61315 |

| Brand |

| NTM | NTM | NTM | NTM |

| Machining Technical Parameters | Max.swing diameter over machine bed | mm | 1600 | 2000 | 2500 | 3150 |

| Max.swing diameter over cutting tool carriage | mm | 1250 | 1650 | 2050 | 2650 |

| Max.work-piece weight | T | 32 | 63 |

| Max.work-piece length | mm | 4000-20000 |

| Machine Bed Parameters | Guide rail type | Rectangle | 4 guide rails |

| Guide rail width | mm | 1600 | 2000 |

| Headstock | Spindle speed |

| Stepless variable frequency |

| Spindle speed range | r/min | 1-100 | 1-100 | 1-100 | 0.5-80 |

| Main motor power | KW | 45 | 55 | 75 | 90 |

| Centers | ° | 75 |

| Max.chuck diameter | mm | 1400 | 1600 | 2000 | 2500 |

| Max. chuck torque | knm | 80 | 120 |

| Feed Data | Max.X axis stroke | mm | 800 | 1000 | 1250 | 1575 |

| Max.Z axis stroke | mm | 4000-20000 |

| Feed range of X Axis | mm | 1-200 |

| Feed range of Z Axis | mm | 1-200 |

| Rapid moving speed of X axis | mm/min | 3000 |

| Rapid moving speed of Z axis | mm/min | 2500 |

| Tailstock | Diameter of tailstock sleeve | mm | 300 | 420 |

| Stroke of tailstock sleeve | mm | 300 |

| Taper of tailstock sleeve | ° | 75 |

| Rapid moving speed of tailstock | mm/min | 1500 |

| Other datas | Machine Length | mm | Depends on the work-piece length |

| Machine Width | mm | 3500 | 3800 | 4000 | 4200 |

| Machine Height | mm | 2300 | 2600 | 3000 | 3500 |

| Control system |

| Touch Operation Panel |

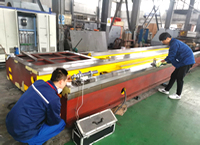

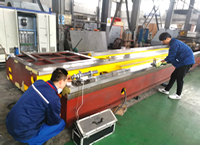

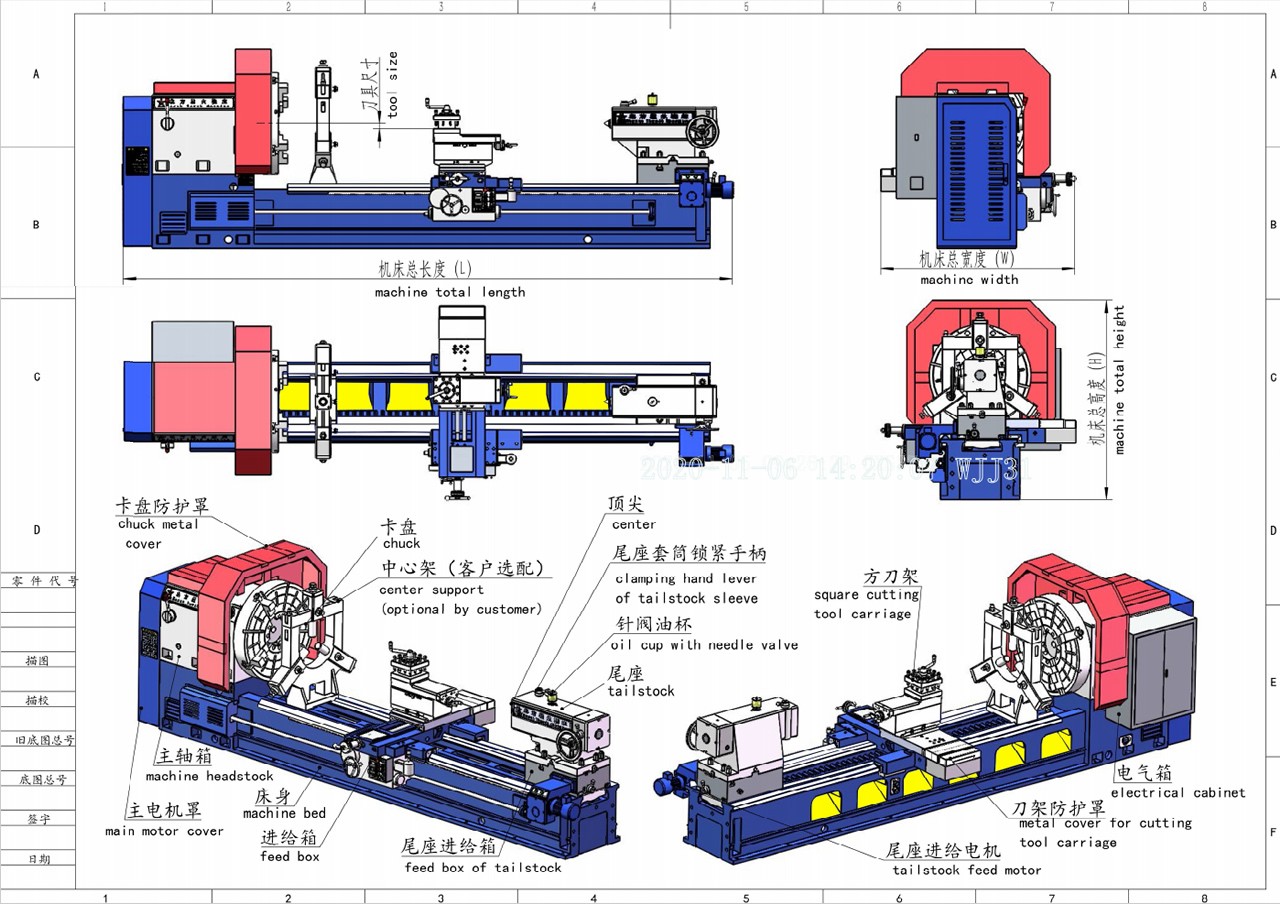

Product Diagram