|

|

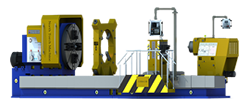

Heavy Duty CNC Lathe Product description

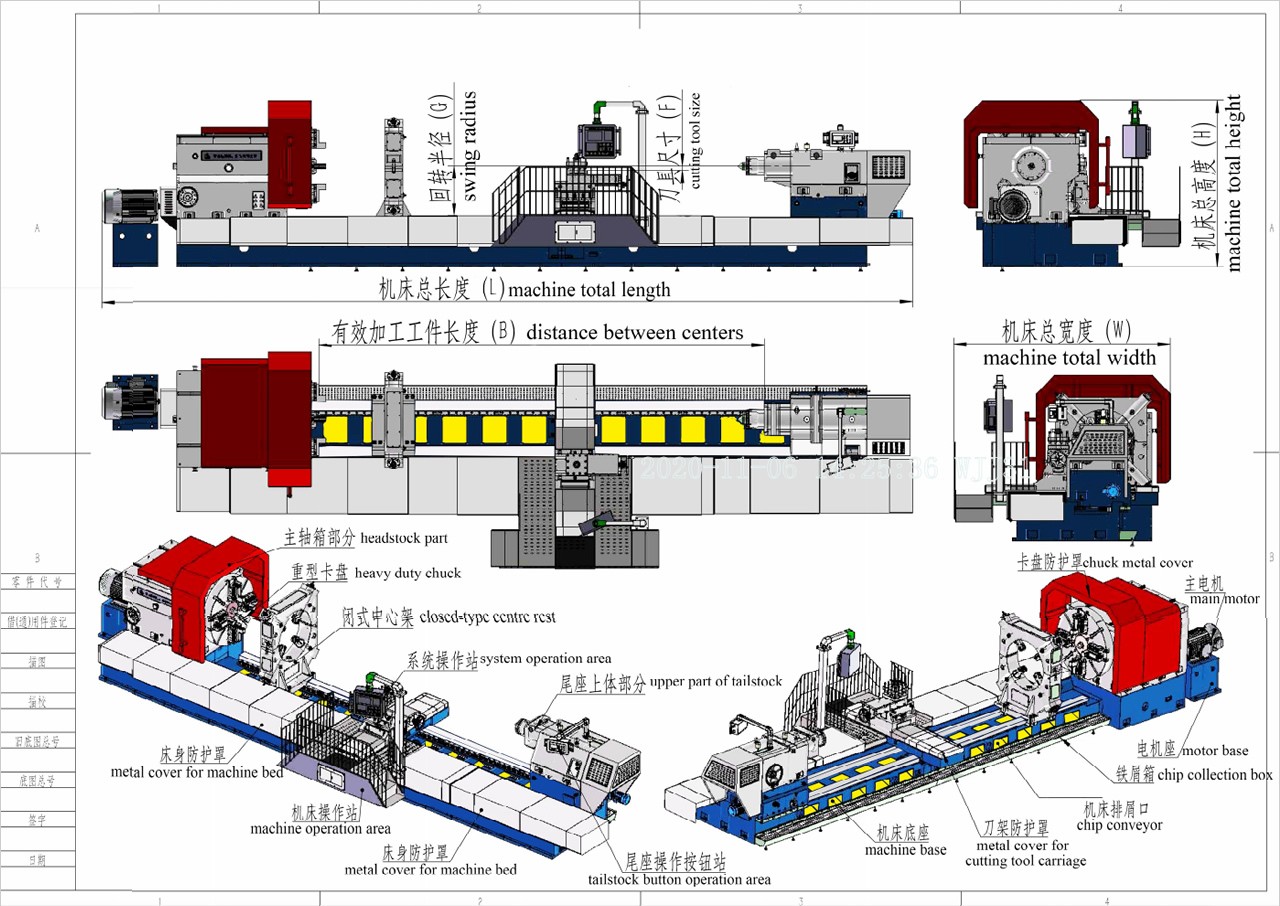

Product DescriptionHeavy Duty Horizontal CNC Lathe Series are widely used for turning not only the non-ferrous metals like various structure steels, casting steels and irons, but also the external/internal cylindrical / conical/ spherical surfaces, thread of non-metal materials and all kinds of the surface of curve rotary body. This machine bed adopts three supporting structure with good rigidity. Designing flexible lateral chip removal system with good performance. Platered structure is adopted between the machine bed guide rail and drag plate. The lathe also has telescopic steel shield/cover to protect the lathe. Besides, this lathe adopts inclined chip removal system with convenient chip removal method. The horizontal direction of cutting tool carriage adopts high precision ball scew. The longitudinal direction adopts high accuracy rack and double tooth rode elimination structure, which improves the transmission accuracy of the cutting tool carriage.This machine is equipped with separate oil pump with excellent lubrication. The tailstock movement adopts mechanical device with reasonable rotation speed, feed rate and power. This kind of lathe has high rigidity, efficiency, energy-saving, easy operation and attractive appearance. CG61 series Heavy Duty Horizontal Lathe Machines designed by my company adopts new-designed and optimized headstock, which utilizes 3D motion simulation to make the spindle box runs more stable. And this design shifts the gears more smoother. And expand the rotation speed range Secondly, integration of automatic feed system. This lathe is installed variable frequency converter and servo motor to improve the automatic level of the machine. Meanwhile, it improves the machine accuracy also and reduce the malfunction of the lathe. Besides, it greatly improves the safety and convenience of the lathe machine。 This lathe has large bearing capacity, strong rigidity and beatiful appearance and easy operation. It is an ideal equipment for machining various steel rollers. Datas

Product Diagram

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||