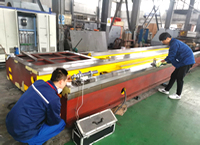

Product description

Conventional Heavy Duty Roll Turning Lathe can machining not only the end face, ex-circle surface, but also the conical surface of various work-pieces. This machine adopts three supporting structure with good rigidity. Designing flexible lateral chip removal system with good performance. This machine is equipped with separate oil pump with excellent lubrication. The tailstock movement adopts mechanical device with reasonable rotation speed, feed rate and power. This kind of lathe has high rigidity, efficiency, energy-saving, easy operation and attractive appearance.

Product Datas

| CX84 Conventional Roll Turning Lathe |

| Model | Unit | CX8465 | CX8480 | CX84100 | CX84125 |

| Brand |

| NTM | NTM | NTM | NTM |

| Machining Technical Parameters | Max.swing diameter over machine bed | mm | 800 | 1000 | 1250 | 1400 |

| Max.swing diameter over cutting tool carriage | mm | 650 | 800 | 1000 | 1250 |

| Max.work-piece weight | T | 6 | 15 | 25 | 32 |

| Max.work-piece length | mm | 2500-6000 |

| Machine Bed Parameters | Guide rail type | Rectangle | 4 guide rails |

| Guide rail width | mm | 1000 | 1250 | 1400 | 1600 |

| Headstock | Spindle speed |

| Stepless variable frequency |

| Spindle speed range | r/min | 1-160 | 1-160 | 0.5-100 | 0.5-100 |

| Main motor power | KW | 30 | 37 | 45 | 75 |

| Centers | ° | 60 | 75 |

| Max.chuck diameter | mm | 600 | 800 | 1000 | 1250 |

| Max. chuck torque | knm | 80 | 120 |

| Feed Data | Max.X axis stroke | mm | 300 | 400 | 400 | 500 |

| Max.Z axis stroke | mm | 2500-6000 |

| Feed range of X Axis | mm | 1-200 |

| Feed range of Z Axis | mm | 1-200 |

| Feed speed of X axis | mm/min | 3000 |

| Feed speed of Z axis | mm/min | 2500 |

| Tailstock | Diameter of tailstock sleeve | mm | 180 | 180 | 240 | 300 |

| Stroke of tailstock sleeve | mm | 300 |

| Taper of tailstock sleeve | ° | 60 | 75 |

| Rapid moving speed of tailstock | mm/min | 1500 |

| Other datas | Machine Length | mm | Depends on the work-piece length |

| Machine Width | mm | 2000 | 2500 | 3000 | 3500 |

| Machine Height | mm | 1500 | 1800 | 2000 | 2200 |

| Control system |

| Touch Operation Panel |

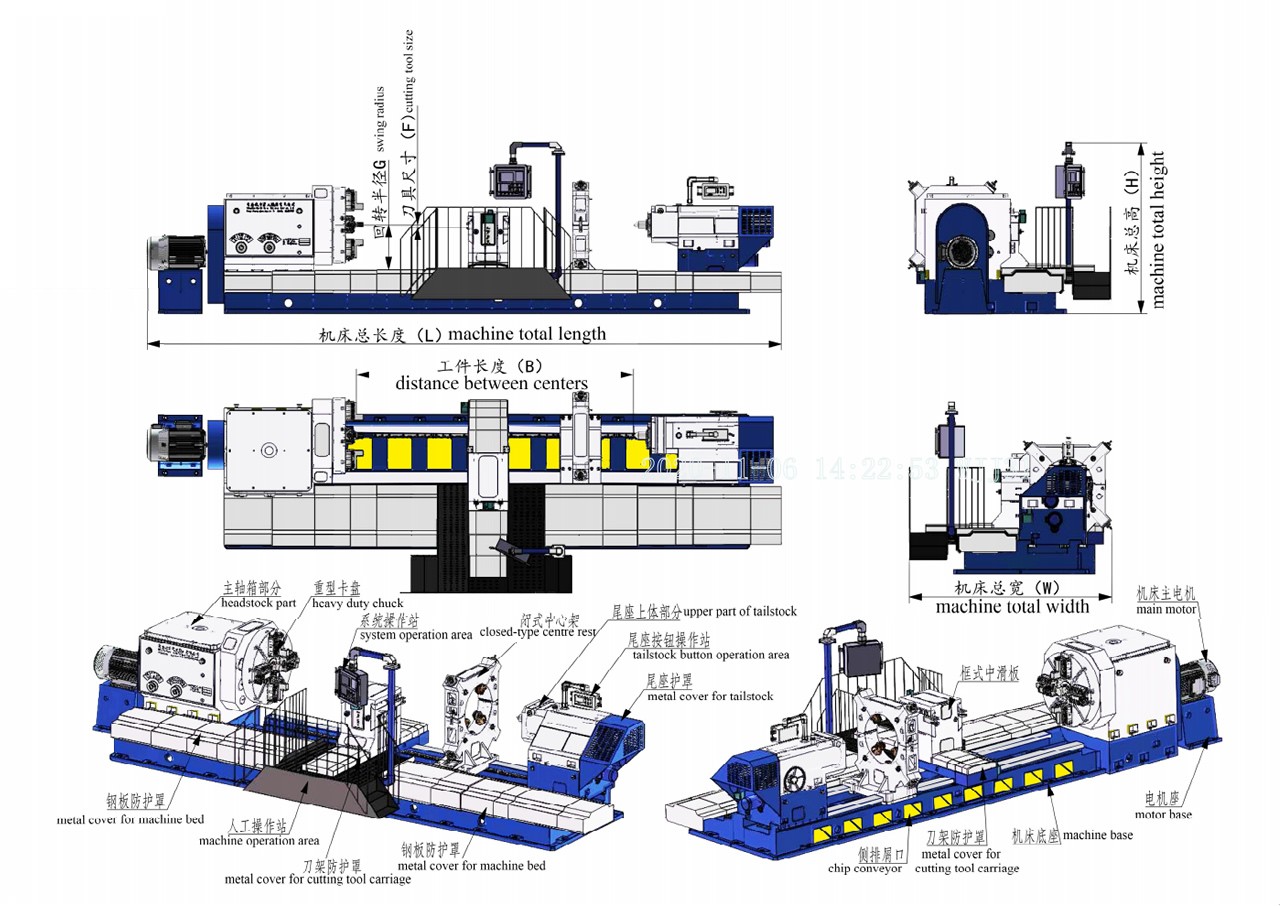

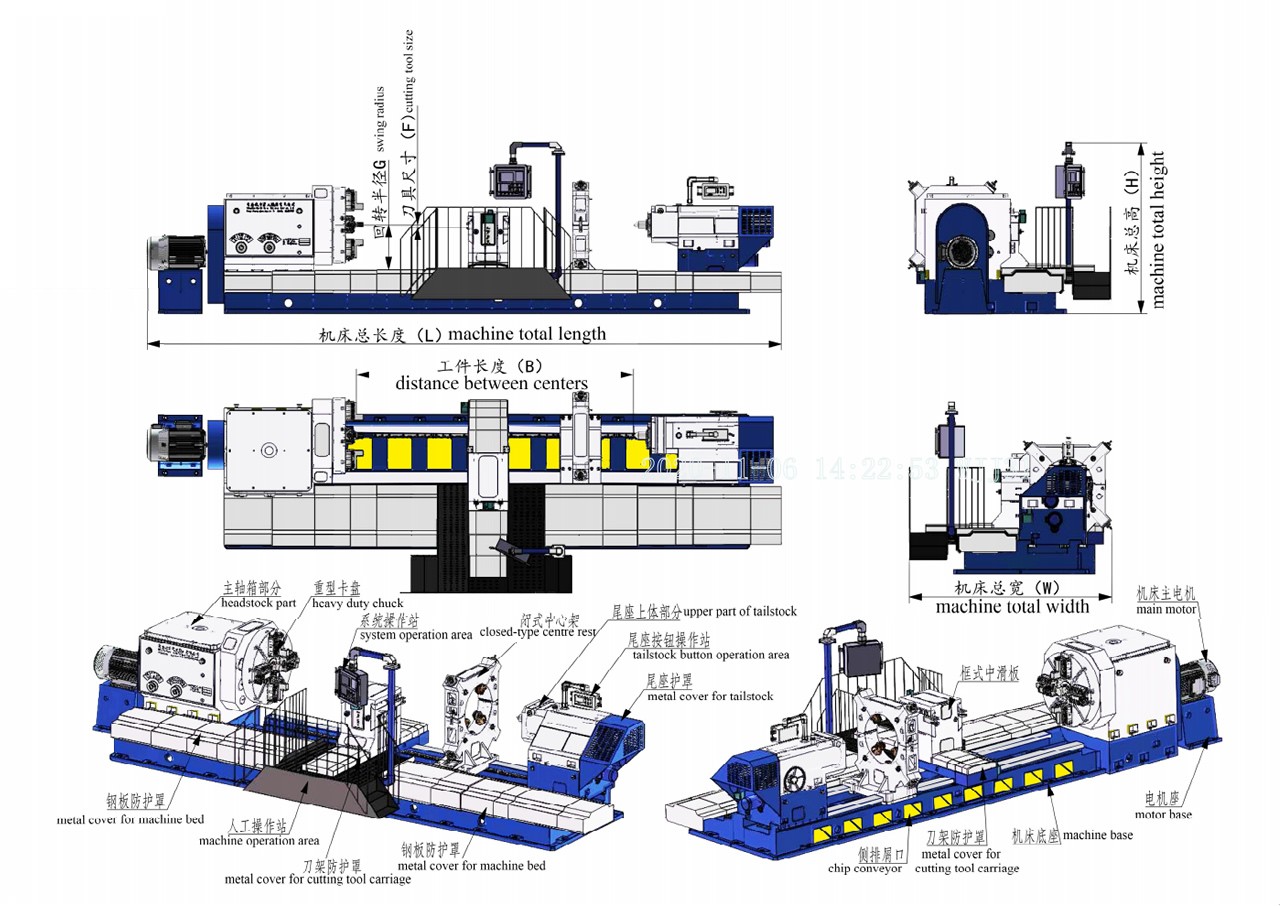

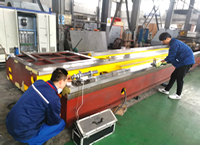

Product Diagram