|

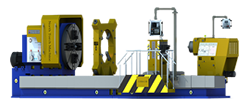

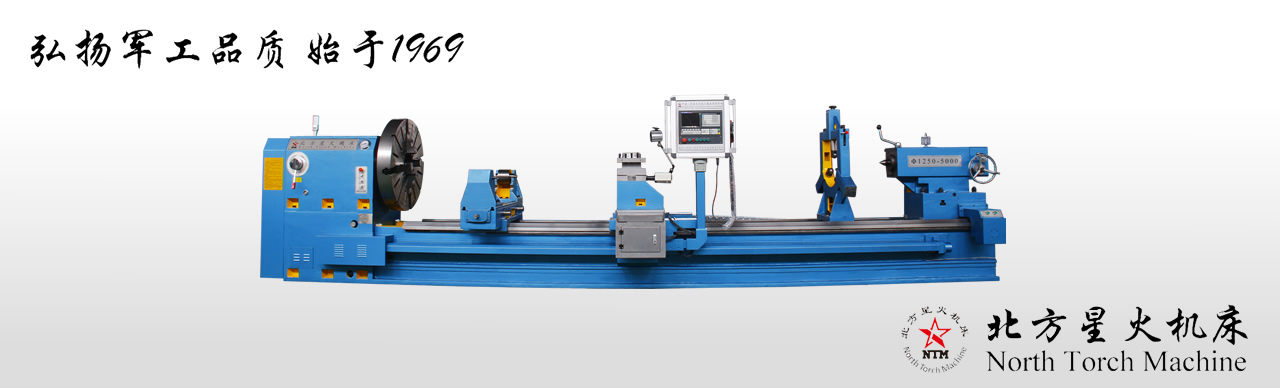

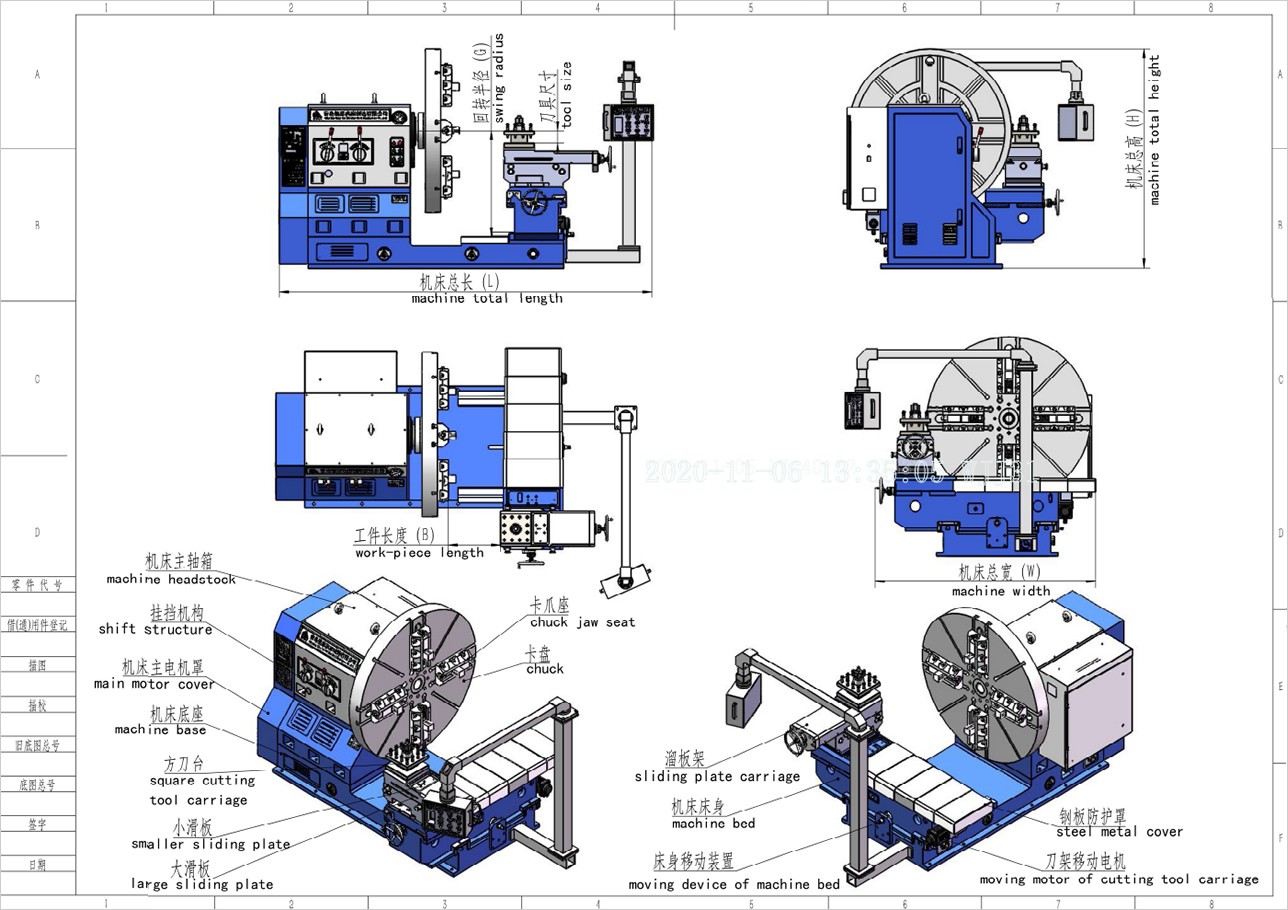

Large Conventional Lathe Product description

Product descriptionConventional Horizontal lathe can realize various turning processes, such as the outer circle, end face, inner hole, cutting groove, thread, R arc and other processes, it is also suitable for hard alloy tools for strong turning, processing a variety of ferrous and non-ferrous metals. The main part of the machine tool uses the international advanced computer technology and the optimization finite element analysis method,which make the lathe has a large load capacity, the design is reasonable, the material choice is exquisite.All castings are made of high strength and high grade Meehanite cast iron, which makes the machine tool has excellent rigidity, stability and accuracy, especially suitable for heavy cutting.All large castings are strictly done by the annealing heat-treatment, coupled with aging treatment, completely eliminate the internal stress, greatly improve the accuracy of the machine, processed parts have excellent geometric precision, the machine base for the cross structure, rectangular stress design, stable organization, reliable, long retention. Product Datas

Product Diagram

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||