|

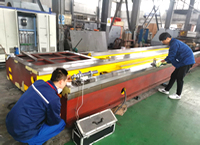

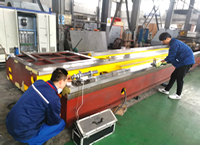

What questions should be paid more attentions on the repairment of guide rail surface of machine bed?Time£º2021-03-29 Attentions about repairment of guide rail surface of horizontal lathe : 1. In order to maintain the guide rail precision and prolong the serving life of lathe machine. It can adopt the quenching method with electrical contact to improve the hardness after repairment of guide rail, finally reach the wear-resisting requirement. 2. The guide rails which adopts high ,medium and ultrasonic frequency quenching methods can not be repaired the precision by scraping, and only be repaired by professional guide-rail grinding machine. No matter adopting either way to repair the guide rail surface, the selected repairing standard and its measurement method are the same in principle. At this time, firstly should test, rectify the installation precision of gear rack, feeding box and bracket, then grinding the guide rail surface to reach the straightness accuracy requirement of guide rail surface. |